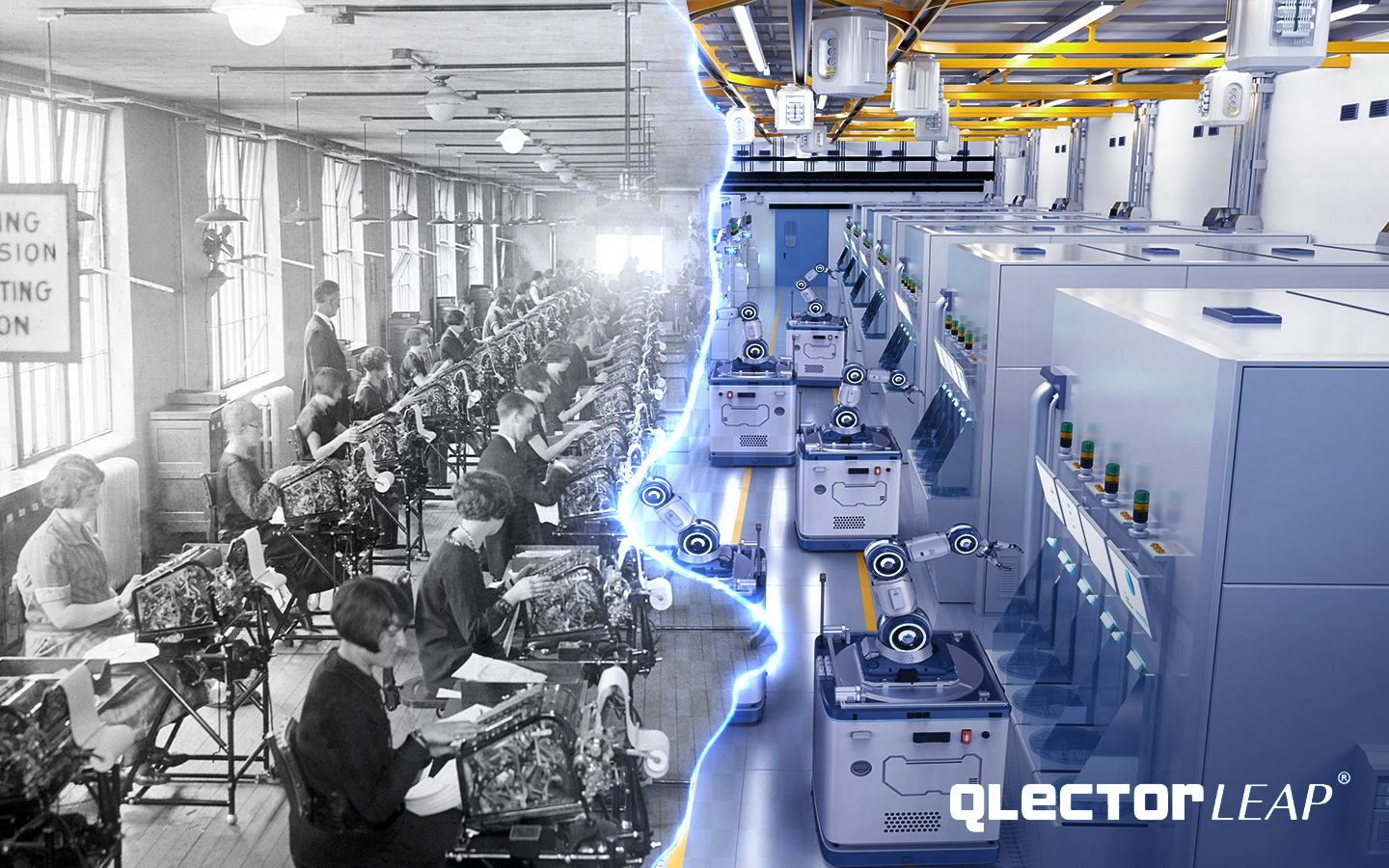

The manufacturing efficiency pursuit through leveraging historical data was and is a crucial strategy. It’s a well-established way to improve and optimize production and scheduling plans. Before advancements in computing and artificial intelligence, manufacturers relied on traditional forms (or Microsoft Excel) to achieve the same goal. Keeping paper records, ledgers, and logbooks was vital, as they later served as a base for a manual statistical analysis of historical data.

Before advancements in computing and artificial intelligence, manufacturers relied on traditional forms (or Microsoft Excel) to achieve the same goal.

With the advancements in computing, data sets could be larger, and the analysis became more practical, precise and quicker. However, today, scouring through historical data by utilizing extensive AI-backed systems to optimize production plans and schedules is much easier, requiring less human input and time.

Possible Issues

Suboptimal production efficiency poses a significant challenge in the manufacturing industry. Utilizing a tool that can review, analyze and tap into historical data to optimize production plans and schedules provides a glimpse into how helpful and informative it can be for shaping the future of manufacturing operations. However, what are some of the challenges that QLECTOR LEAP can assist with:

- Lack of insights into performance trends

- Reactive planning

- Inefficient resource utilization

- Repetitive setbacks

Here to Help

We are here to help. QLECTOR LEAP is a comprehensive platform designed to revolutionize the implementation of advanced production planning and scheduling to streamline and optimize your production processes.

Harnessing Historical Insights

Delving into historical data provides invaluable insights into past production performance, from which identifying patterns, trends, and areas for improvement are made possible. QLECTOR LEAP’s Digital Twin module is a scalable data-driven replica of the factory. It identifies anomalies and enhances the accuracy of master data, ensuring realistic production schedules based on historical insights.

Predictive Analytics for Proactive Planning

Leveraging historical data enables the application of predictive analytics, forecasting potential challenges or opportunities in production scheduling. The Production Guiding module integrates Next-Gen APS technologies for sophisticated sequencing of production orders, anomaly detection, and data-driven decision-making. It enables proactive planning through predictive analytics, ensuring greater adaptability.

Continuous Improvement Through Analysis

Regular analysis of historical production data allows manufacturers to identify areas for continuous improvement. The Digital Twin module facilitates continuous improvement by monitoring and understanding the whole scope of the production process, comparing datasets between ERP norms and real-time shop floor data, a vital part of achieving cost reduction and heightened operational efficiency.

Learning from Challenges and Successes

Examining historical data provides an opportunity to learn from both challenges and successes. The production optimization module of the QLECTOR LEAP emphasizes adaptability, predicting and simulating potential events while offering actionable insights. Minimizing the necessity for human intervention and enabling proactive measures against uncertainty, the Production Optimization module serves as a key tool for achieving continuous improvement.

Conclusion

In the quest for manufacturing efficiency, leveraging historical data is a cornerstone strategy, offering a well-established pathway to enhance and optimize production and scheduling plans. In the pre-digital era, manufacturers leaned on traditional methods and manual analysis. The advent of computing ushered in a new era, enabling larger datasets and more precise analyses. As the evolution continues, AI production planning takes precedence today. QLECTOR LEAP allows the optimization of production plans and schedules to be more accessible, efficient, and less time-consuming.