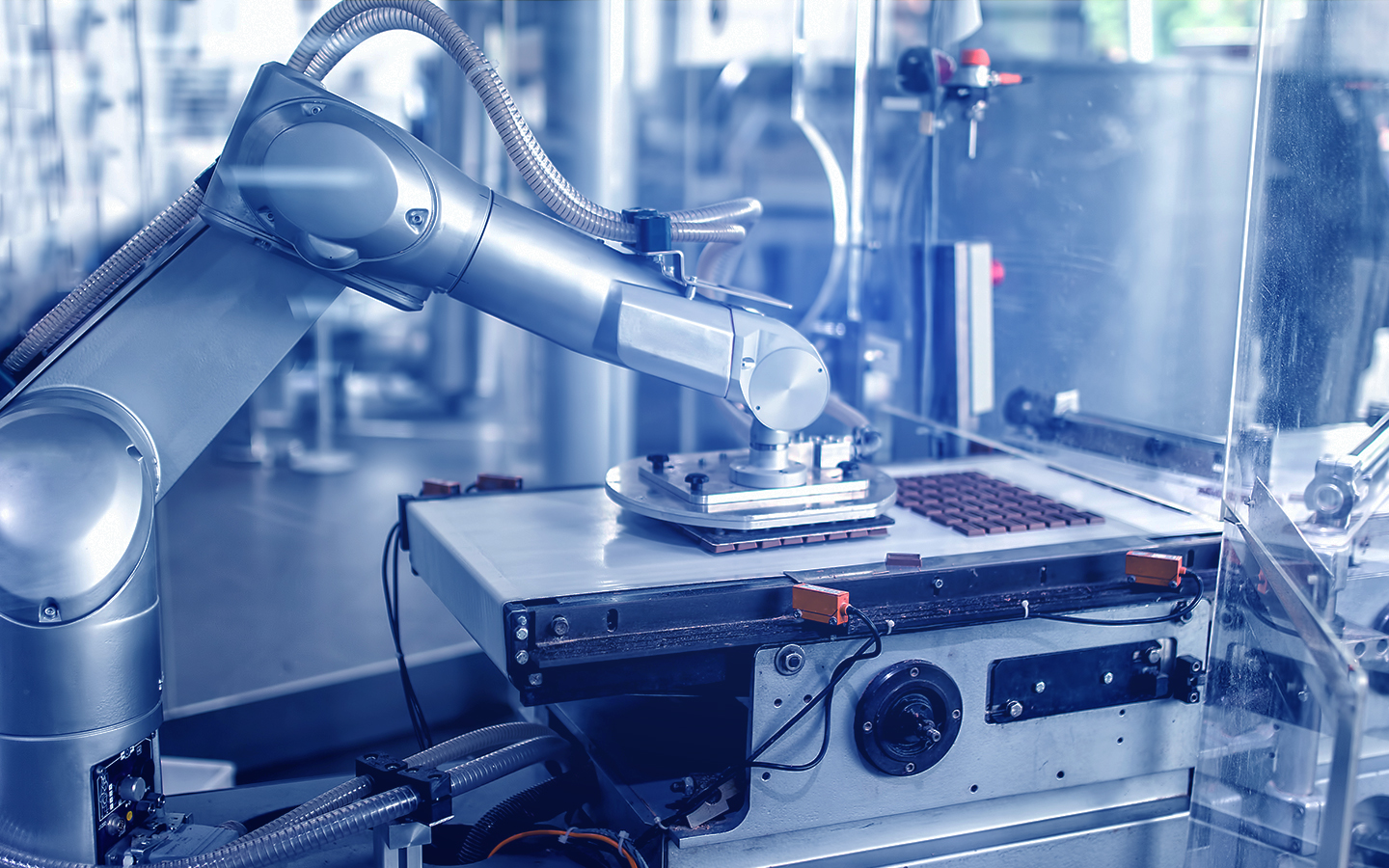

Chocolate – the sweet, indulgent treat that has delighted our taste buds for centuries. But behind every delectable bar lies a complex production process. From cocoa bean sourcing to tempering and packaging, chocolate manufacturing involves intricate steps that need seamless coordination. Enter QLECTOR LEAP, a powerful tool that revolutionizes chocolate production by enhancing efficiency, streamlining processes, and minimizing hiccups.

For companies seeking to maintain consistent quality while scaling production, embracing this innovative solution is the key to staying ahead.

The Digital Twin: A virtual factory in your pocket

Imagine having a miniature, data-driven replica of your chocolate factory – a virtual twin that mirrors every conveyor belt, tempering machine, and cocoa grinder. That’s precisely what QLECTOR LEAP’s Digital Twin Module offers. Here’s how it works:

- Understanding the factory: QLECTOR LEAP creates a cognitive digital twin that learns from real-world data. It understands the nuances of your factory, from raw material intake to finished product dispatch.

- Knowledge graphs: This virtual twin maintains a knowledge graph, connecting the dots between different processes. For chocolate manufacturers, it means insights into production bottlenecks, resource utilization, and quality control.

- Predictive insights: By analyzing historical data, the digital twin predicts potential issues. Whether it’s a malfunctioning tempering machine or an unexpected surge in demand, QLECTOR LEAP alerts you in advance.

Master Data Management: The backbone of efficiency

Master data – the beating heart of any production system. QLECTOR LEAP’s Master Data Management (MDM) Assistant ensures that your master data is accurate, up-to-date, and aligned with reality:

- Anomaly detection: By comparing theoretical norms (ERP data) with real-time shop floor data (MES), QLECTOR LEAP spots discrepancies. For chocolate makers, this means precise material planning, realistic production schedules, and optimized inventory levels.

- Resource allocation: Imagine allocating workers, machines, and ingredients based on accurate data. The MDM Assistant ensures that your chocolate factory hums along smoothly, avoiding overcommitment or underutilization.

- Seamless integration: QLECTOR LEAP bridges the gap between departments. It’s like having a friendly mediator who ensures that production, logistics, and quality control speak the same language.

A Sweet Future with QLECTOR LEAP

In the world of chocolate production, advanced planning and scheduling are no longer buzzwords – they’re essential. QLECTOR LEAP transforms factories into smart, agile ecosystems. So, the next time you savor that velvety chocolate square, remember the unsung hero behind it – technology that ensures every bite is perfection.

To wrap up

QLECTOR LEAP is a game-changer for chocolate manufacturing, seamlessly merging data-driven insights with advanced planning and scheduling. Whether it’s predicting potential bottlenecks, ensuring optimal resource allocation, or integrating operations across departments, QLECTOR LEAP empowers your production process from start to finish.